A Comprehensive Guide to Recognizing Litho Printing Methods

The world of litho printing, a method originating from the late 18th century, is a fascinating mix of history, science, art and development. This extensive overview will certainly unwind the intricacies of this printing technique, from the composition of litho inks to the difficulties encountered in modern-day applications. As we venture into the intricacies of lithography, the significance of automation and sustainability in guaranteeing its future relevance becomes increasingly clear. Remain with us as we trip into the fascinating world of litho printing.

The Historic Development of Litho Printing

The historic trajectory of litho printing, a critical innovation in the realm of communication, is a fascinating tale of human resourcefulness. The process developed with the introduction of the rotating press, which substantially raised efficiency. Each stage of litho printing's evolution showcases humanity's ruthless pursuit of effectiveness and quality in aesthetic communication.

Decoding the Science Behind Litho Printing Inks

Moving on in the exploration of litho printing strategies, the emphasis currently changes to the science behind litho printing inks. The composition of these inks, their drying out procedure, and shade mixing techniques form the foundation of this complex art kind. Understanding these elements is critical to understanding the craft and achieving the desired print outcomes.

Make-up of Litho Inks

In lithographic printing, the basic duty of litho inks can not be overemphasized. The make-up of litho inks varies relying on its purpose, yet normally, they are composed of two main components - cars and pigments. Pigments, the color-providing aspects, are carefully ground particles suspended in the vehicle, a liquid that lugs the pigment onto the printing surface area. The lorry is an intricate mixture of solvents, materials, and oils, which affect the ink's drying time, bond, and gloss. Furthermore, different ingredients are existing to boost specific residential properties like circulation, drying out, and resistance to environmental impacts. Each component plays a critical component in the final print's top quality, making the specific formulation of litho inks a detailed science.

Ink Drying Process

From the structure of litho inks, focus transforms to the fascinating process of ink drying out. The drying out procedure is vital, as it affects the final print's high quality and longevity. 2 key approaches are used in litho printing: oxidative drying and absorption. Oxidative drying out entails the ink reacting with oxygen airborne to create a hard, completely dry movie. This technique supplies a resilient coating, yet can be slower contrasted to absorption. Absorption, on the other hand, includes the ink leaking into the paper fibers, which is a faster procedure but can lead to less lively colors. The selection between these techniques depends on aspects such as print rate needs, the paper kind used, and the wanted surface.

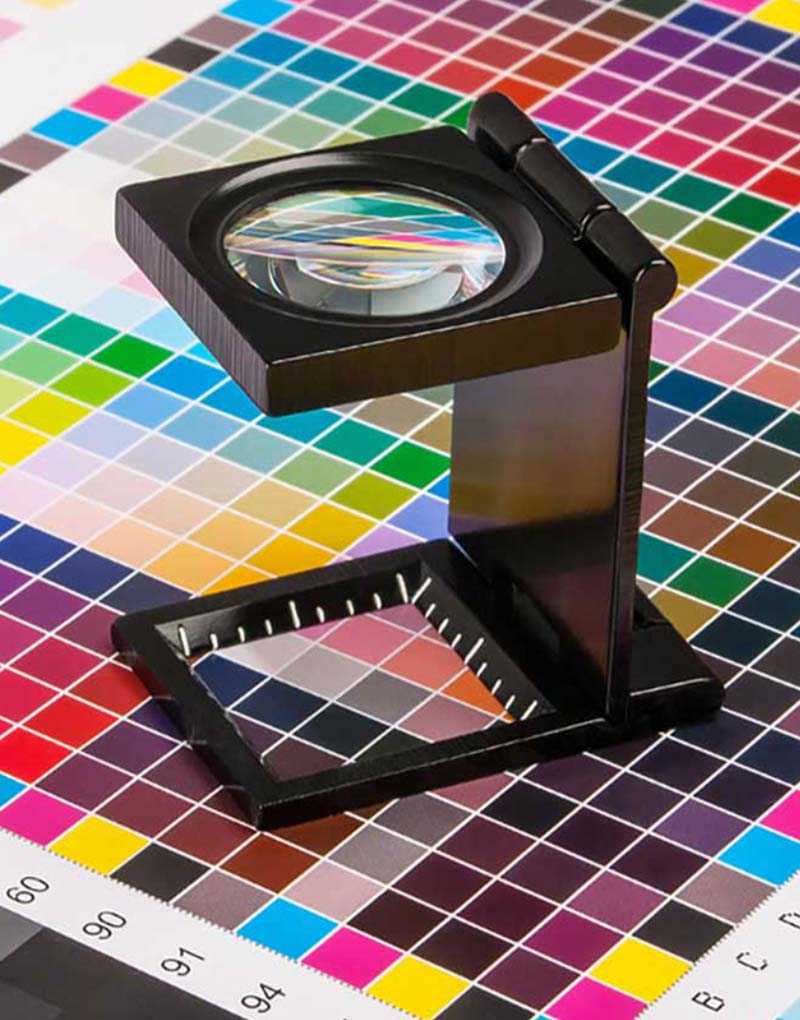

Color Combining Techniques

While the drying process plays an essential function in litho printing, the scientific research of shade blending methods holds equal importance. This is a complicated procedure that includes the mindful blending of primaries: cyan, magenta, and yellow, in differing proportions to achieve a broad array of hues. The addition of black ink, called 'essential', aids in controling the strength and depth of the colors. The science behind litho printing inks also takes into consideration the openness of the ink, which impacts how shades overlay and mix. To accomplish an efficient shade mix, print experts must likewise comprehend the intricacies of ink habits, shade concept, and the physical buildings of the substrate on which the ink is used.

The Art and Design Elements in Litho Printing

Litho printing breathes life right into art and layout with its distinct aspects. Litho printing suits a range of colors, enabling artists to produce look what i found lively and dynamic prints. This mix of precision and adaptability makes litho printing a recommended option for numerous artists and developers.

Modern Applications of Litho Printing Strategies

Litho printing methods have actually located comprehensive use in the modern industrial field. Its influence and value remain to grow with the advent of new technologies and modern technologies in the field. This section will discover these modern applications and the transformative duty they play in the printing sector.

Business Litho Printing Utilizes

Litho printing stays a vital component of the industrial market. High-volume printing jobs, such as the production of publications, papers, and product packaging, rely on litho printing for its ability to deliver premium photo quality and expense effectiveness. Litho printing likewise supplies a wide color range, superior to that of electronic printing.

Innovations in Litho Printing

Pressing the borders of traditional methods, contemporary developments have actually fueled a host of technologies in litho printing. One famous advancement is digital litho printing, which incorporates the virtues of digital innovation with litho's top quality result. visit this page These innovations highlight the enduring importance of litho printing in the modern world.

Exploring the Refine of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

In spite of the precision and practice that litho printing proudly supports, it is not without its set of contemporary difficulties. Digital litho printing enables for affordable brief runs and very easy modification, resolving the issue of variable data. Hence, while there are this contact form difficulties, the litho printing industry is proactively adjusting to satisfy them head-on, ensuring its importance in the future.

Verdict

In conclusion, litho printing, with its rich background and clinical ins and outs, holds a significant location in the print market. The future of litho printing pivots on its capability to adjust to these altering needs, affirming its long-lasting worth in a progressing market.